Electrical and Electronics Engineering Portal!

BRIDGE NETWORK

The dc level obtained from a sinusoidal input can be improved to cent

percent using a process called full wave rectification. The most commonly used

circuit for performing this function is the bridge circuit with four diodes. The circuit

diagram of the Bridge rectifier and the input waveform is given below.

The input waveform is given as,

The diodes D2 and D3 conduct while D1 and D4 are in “off” state.

The configuration showing the current and polarity across the resistor R

during the first half cycle (or positive region of the input) is shown below.

The input and output waveform during the above cycle is shown below.

The voltage level Vdc for full wave rectifier is twice as much as that for a half

wave rectifier.

Center Tapped Transformer:

The circuit for the full wave rectifier using two pn diode, load resistor RL and

a center tapped transformer to supply the input of the secondary to both the diodes

equally is shown below.

Operation

When the input voltage from the secondary of the transformer is positive, D1

conducts since it is forward biased. D2 is open circuit since it is reverse biased. The

current is passed through the diode and obtained across the load resistor.

When the input voltage from the secondary of the transformer is negative, D2

conducts since it is forward biased. D2 is open circuit since it is reverse biased. The

current is passed through the diode and obtained across the load resistor.

Hence, for both the positive and negative going voltage there is voltage at the

output of the FWR.

Let vi be the input voltage obtained the transformer secondary.

Vi = Vm sinwt = Vm sin a ---(5.1.26)

Where, Vm is the amplitude of the input voltage (v), w is the angular

frequency in radians/second. a is in radians.

Single Phase Rectifiers

Half wave Rectifier:

Figure gives the circuit for the halfwave-rectifier using a pn diode, resistor RL and a

transformer to get the input in the secondary. Let vi be the input voltage obtained the

transformer secondary.

Vi = Vm sinwt = Vm sin a ---(5.1.1)

Where, Vm is the amplitude of the input voltage(v),w is the angular frequency in

radians/second. a is in radians.

Let the amplitude Vm >> Vv where,Vv is the cutin voltage for the pn diode.

Assuming Vv = 0. Let the diode be ideal with resistance Rf in the ON state and Rf =& in the OFF state.The current through the diode and the load resistor RL is given

by

i = Im sina for 0<= a <= p

i = 0 for p<=a<=2 p ----(5.1.2)

where Im is the peak current given by

Im = Vm ---(5.1.3)

Rf + RL

Current flowing through RL will produce a output voltage vo given by

vo = i x RL ---(5.1.4)

DC or Average Current Idc

2p

Idc = 1 œ L G DOSKD ---(5.1.5)

2 p 0

where i is given by the equation (5.1.2).

Current i = 0 when p < t< 2 p

p

Idc = 1 œL G DOSKD Im ---(5.1.6)

2 p 0 p

and Idc = Vm ---(5.1.7)

p(Rf+RL)

DC Output Voltage Vdc

Vdc = Idc . RL = Im . RL ---(5.1.8)

= Vm ---(5.1.9)

p(1 + Rf/RL)

The Diode Voltage: It is the instantaneous voltage across the diode ( i . R , where R

is the diode resistance. = Rf when ON and =OO When OFF). The wave form is shown in

the figure below

Merits of Half-wave Rectifier:

(i) simple circuit

(ii) low cost.

Disadvantage of Halfwave:

(i) Low rectifier efficiency

(ii) High ripple factor

(iii) Low TUF

(iv) DC saturation of the transformer core due to flow of current in the secondary of

the power transformer. The DC saturation of the core increases the magnetising

current and the hysterisis losses and produces harmonics in the output of the

secondary.

Figure gives the circuit for the halfwave-rectifier using a pn diode, resistor RL and a

transformer to get the input in the secondary. Let vi be the input voltage obtained the

transformer secondary.

Vi = Vm sinwt = Vm sin a ---(5.1.1)

Where, Vm is the amplitude of the input voltage(v),w is the angular frequency in

radians/second. a is in radians.

Assuming Vv = 0. Let the diode be ideal with resistance Rf in the ON state and Rf =& in the OFF state.The current through the diode and the load resistor RL is given

by

i = Im sina for 0<= a <= p

i = 0 for p<=a<=2 p ----(5.1.2)

where Im is the peak current given by

Im = Vm ---(5.1.3)

Rf + RL

vo = i x RL ---(5.1.4)

DC or Average Current Idc

2p

Idc = 1 œ L G DOSKD ---(5.1.5)

2 p 0

where i is given by the equation (5.1.2).

Current i = 0 when p < t< 2 p

p

Idc = 1 œL G DOSKD Im ---(5.1.6)

2 p 0 p

and Idc = Vm ---(5.1.7)

p(Rf+RL)

DC Output Voltage Vdc

Vdc = Idc . RL = Im . RL ---(5.1.8)

= Vm ---(5.1.9)

p(1 + Rf/RL)

The Diode Voltage: It is the instantaneous voltage across the diode ( i . R , where R

is the diode resistance. = Rf when ON and =OO When OFF). The wave form is shown in

the figure below

(i) simple circuit

(ii) low cost.

Disadvantage of Halfwave:

(i) Low rectifier efficiency

(ii) High ripple factor

(iii) Low TUF

(iv) DC saturation of the transformer core due to flow of current in the secondary of

the power transformer. The DC saturation of the core increases the magnetising

current and the hysterisis losses and produces harmonics in the output of the

secondary.

The OperaTion of PerManent Magnet DC moTors

Permanent magnet synchronous motor:

Shown in Fig. 6.3 is a surface-mounted magnet machine with an airgap,

or surface armature winding. Such machines take advantage of the fact that modern, permanent magnet materials have very low permeabilities and that, therefore, the magnetic field produced is relatively insensitive to the size of the air-gap of the machine. It is possible to eliminate the stator teeth and use all of the periphery of the air-gap for windings.

2.875 OD x .875 ID x .250 Lg., Ring, Ceramic, Permanent Magnet

Not shown in this figure is the structure of thee armature winding.

This is not an issue in “conventional” stators, since the armature is contained in slots in the iron stator core. The use of an air-gap winding

gives opportunities for economy of construction, new armature winding

forms such as helical windings, elimination of “cogging” torques and

(possibly) higher power densities

Search More Magnet DC motors

The Working Principle of Variable Reluctance Motor

VARIABLE RELUCTANCE MOTORS

o Self starting capability.

OPERATION

- It is the most basic type of stepper motor. This helps to explain the principle of operation of the stepper motors.

- The motor has a stator which is usually wound for three phases.

- The stator has six salient poles with concentrated exciting windings around each one of them. The stator construction is laminated and assembled in a single stack.

- The number of poles on the stator and rotor are different. This gives the motor ability,

o Self starting capability.

- The rotor is made out of slotted steel laminations. If the number of stator poles are N and the number of rotor poles are Nr then for a. three phase motor, the rotor poles in terms N q are given by,

- where q = Number of phases For example for N =6 and

- For our discussion, 4 pole rotor constructi6n is elected. So rotor has 4 salient poles without any exciting winding as shown in the Fig. 7.6.

- The coils wound around diametrically opposite poles are connected in series and the three phases are energized from a d.c. source with the help of switches.

- The basics driving circuit is shown in the Fig. 7.7.

OPERATION

- The operation is based on various reluctance positions of rotor with respect to t When any one phase of the stator is excited, it produces its magnetic field whose axis I along the poles, the phase around which is excited.

- Then rotor moves in such a direction as to achieve minimum reluctance position. Such a position means a position where axis magnetic field of stator matches with the axis passing through any two poles of the rotor.

- Let us see the operation when phases A, B and C are energized in sequence one after the other, with the help of switches SW1, SW2, and SW3.

- When the phase AA’is excited with the switch SW1 closed, then stator magnetic axis exists along the poles formed due to AA 1 e vertical

- Then rotor adjusts itself in a minimum reluctance position i.e. matching its own axis passing through the two poles exactly wit stator magnetic axis.

- This position is shown in the Fig. 7.8 (a)

- When the phase BB’ is excited with the switch SW closed and phase AA’ de energized with the switch SW open, then stator magnetic axis shifts along the pales formed due to BB’, shown dotted in the Fig. 7.8 (b).

- Then rotor tries to align in the minimum reluctance position and turns through 3Ø in anticlockwise direction.

- So axis passing through two diagonally opposite poles of rotor matches with the stator magnetic axis. This is the new minimum reluctance position.

- The point P shown on the rotor has rotated through 30° in anticlockwise direction as shown in the Fig. 7.8 (b)

- When the phase CC’ is excited with the switch SW closed and the phases AA’ and B are de energized, then the stator magnetic axis shifts along the poles formed due to CC’, shown dotted in the Fig. 7.8 (c).

- Then to achieve minimum reluctance position, rotor gets subjected to further anticlockwise torque. So it turns through further 30° in anticlockwise direction.

- Hence point P is now at 6G° from its starting position, in anticlockwise direction as shown in the Fig. 7.8 (c).

- By successively exciting the three phases in the specific sequence, the motor takes twelve steps to complete one resolution.

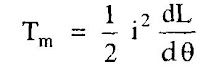

- Now if i is the current passing through the phase which is excited then the torque developed by the motor, which acts on the rotor is expressed as,

- where L is the inductance of the relevant phase at an angle 0.

- Since the torque is proportional to the square of the phase current (T x i ) , it is independent of the direction of i.

- The direction of rotation is totally decided from the sequence in which the phases are excited.

HYSTERESIS MOTOR DEFINITIONS

HYSTERESIS MOTOR

This is the synchronous motor which does not require any d.c. excitation to the rotor and it uses non projected poles.It consists of a stator which carries main and auxiliary windings so as to produce rotating magnetic field. The stator can also be shaded pole type. The rotor is smooth cylindrical type made up of hard magnetic material like chrome steel or alnico for high retentivity.This requires selecting a material with high hysteresis loop area. The rotor does not carry any winding.The construction is shown in the Fig. 7.4 (a) while nature of hysteresis loop required for rotor material.

|

| (a) Cross-sectional view of hysteresis motor (b) Hysteresis loop for rotor material |

- When stator is energized, it produces rotating magnetic field. The main and both the winding must be supplied continuously at start as well as in running core as to maintain the rotating magnetic field.

- This field induces poles in the hysteresis phenomenon is dominant for the rotor material chosen and due to which pole axis lag behind the axis of rotating magnetic field. Due to this, rotor poles get a towards the moving stator field poles.

- Thus rotor gets subjected to torque called hysteresis torque. This torque is constant at all speeds. When the stator field axis moves forward to high retentivity the rotor pole strength remains maintained.

- So higher the r higher is the hysteresis torque. Initially rotor starts rotating due to combined effect of hysteresis torque as well a due to eddy currents induced in the rotor. Once the speed is near about the synchronous stator pulls rotor into synchronism.

- In such case, as relative motion between stator field rotor vanishes, so the torque due to eddy currents vanishes. Only hysteresis t present which keeps rotor running at synchronous speed. The high retentivity ensures continuous magnetic locking between stator and rotor.

- Due to principle of magnetic I the motor either rotates at synchronous speed or not at all.

MATHEMATICAL ANALYSIS

- The eddy current loss in the machines is given by,

- We know the relation between rotor frequency f and supply frequency f,

- The torque due to eddy currents is given by

- So when rotor rotates at synchronous speed, the slip becomes zero and torque eddy current component vanishes. It only helps at start.

- The hysteresis loss is given by,

- The corresponding torque is given by,

TORQUE-SPEED CHARACTERISTICS

- The starting torque and running torque is almost equal in this type of motor.

- As stator carries mainly the two windings its direction can be reversed by interchanging the terminals of either main winding or auxiliary winding.

- The torque-speed characteristic is as shown in the Fig. 7.5.

- As seen from the characteristics torque at start is almost same throughout the operation of the motor.

Advantages

- The advantages of this motor are:

- As rotor has no teeth, no winding, there are no mechanical vibrations.

- Due to absence of vibrations, the operation is quiet and noiseless.

- Suitability to accelerate high inertia loads

- Possibility of multi speed operation by employing gear train.

Applications

- Due to noiseless operation it is used in sound recording instruments, sound producing equipments, high quality record players, tape recorders, electric clocks, teleprinters, timing devices etc.

The Operation of Reluctance Motor with Diagram

Reluctance Motor

Fig. 7.1 Reluctance motor

WORKING PRINCIPLE

MATHEMATICAL ANALYSIS

Consider an elementary reluctance motor as shown in the Fig. 7.2

TORQUE-SPEED CHARACTERISTICS

The torque-speed characteristic is shown in the Fig. 7.3 The starting torque is highly dependent on the position of the rotor.

Fig. 7.3 Torque-speed characteristics of reluctance motor

ADVANTAGES

LIMITATIONS

APPLICATIONS

- The reluctance motor has basically two main parts called stator and rotor.

- The stator has a laminated construction, made up of stampings.

- The stampings are slotted on its periphery to carry the winding called stator winding. The stator carries only one winding.

- This is excited by single phase a.c. supply. The laminated construction keeps iron losses to minimum.

- The stampings are made up of material like silicon steel which minimises the hysteresis loss.

- The stator winding is wound for certain definite number of poles.

- The rotor has a particular shape. Due to its shape, the air gap between stator and rotor is not uniform. No d.c. supply is given to the rotor.

- The rotor is free to rotate. The reluctance i.e. resistance of magnetic circuit depends on the air gap.

- More the air gap, more is the reluctance and viceversa. Due to variable air gap between stator and rotor, when rotor rotates, reluctance between stator and rotor also changes.

- The stator and rotor are designed in such a manner that the variation of the inductance of the windings is sinusoidal with respect to the rotor position.

- The construction of the reluctance motor is shown in the Fig. 7.1(a) while the practical rotor of a reluctance motor is shown in the Fig. 7.1(b)

Fig. 7.1 Reluctance motor

WORKING PRINCIPLE

- The stator consists of a single winding called main winding. But single winding can not produce rotating magnetic field. So for production of rotating magnetic field, there must be at least two windings separated by certain phase angle.

- Hence stator consists of an additional winding called auxiliary winding which consists of capacitor in series with it.

- Thus there exists a phase difference between the currents carried by the two windings and corresponding fluxes.

- Such two fluxes react to produce the rotating magnetic field. The technique is called split phase technique of production of rotating magnetic field.

- The speed of this field is synchronous speed which is decided by the number of poles for which stator winding is wound.

- The rotor carries the short circuited copper or aluminium bars and it acts as squirrel cage rotor of an induction motor.

- If an iron piece is placed in a magnetic field, it aligns itself in a minimum reluctance position and gets locked magnetically.

- Similarly in the reluctance motor, rotor tries to align itself with the axis of rotating magnetic field in a minimum reluctance position.

- But due to rotor inertia it is not possible when rotor is standstill. So rotor starts rotating near synchronous speed as a squirrel cage induction motor.

- When the rotor speed is about synchronous, stator magnetic field pulls rotor into synchronism i.e. minimum reluctance position and keeps it magnetically locked.

- Then rotor continues to rotate with a speed equal to synchronous speed. Such a torque exerted on the rotor is called the reluctance torque.

- Thus finally the reluctance motor runs as a synchronous motor. The resistance of the rotor must be very small and the combined inertia of the rotor and the load should be small to run the motor as a synchronous motor

MATHEMATICAL ANALYSIS

Consider an elementary reluctance motor as shown in the Fig. 7.2

- The variation of the inductance of the windings is sinusoidal with respect to rotor position.

- The variation of the inductance with respect toO is of double frequency and is given by,

- The stator winding is exciteal by a.c. supply hence

- The energy stored is a function of inductance and given by,

- The flux linkage is given by,

- Then the torque is given by

- Substituting the values of i and L,

- If rotor is rotating at an angular velocity corn then finally the torque equation can be expressed interms of ω and ωm as,

- The above equation gives instantaneous torque produced. The average torque is zero as average of each term in the above equation is zero.

- The value of torque is not zero when ω = ωm and at this condition the magnitude of the average torque is,

- The speed corresponding to the frequency ω = ωm is nothing but the synchronous speed. The is a torque angle. The maximum torque occurs at δ = 45º which is termed as pull-out torque.of synchronism.

TORQUE-SPEED CHARACTERISTICS

The torque-speed characteristic is shown in the Fig. 7.3 The starting torque is highly dependent on the position of the rotor.

Fig. 7.3 Torque-speed characteristics of reluctance motor

ADVANTAGES

- The reluctance motor has following advantages,

- No d.c. supply is necessary for rotor.

- Constant speed characteristics.

- Robust construction.

- Less maintenance.

LIMITATIONS

- The reluctance motor has following limitations,

- Less efficiency

- Poor power factor

- Need of very low inertia rotor.

- Less capacity to drive the loads.

APPLICATIONS

- This motor is used in signaling devices, control apparatus, automatic regulators, recording instruments, clocks and all kinds of timing devices, teleprinters, gramophones etc.

Advantage of an AC Series Motor and Application of Linear Induction Motor

SEARCH MORE APPLICATIONS HERE

Industrial application opportunities

Two different opportunities to implement linear drives are shown at the following pictures.

Duracell Products - Duracell - Procell Alkaline Battery, 9V, 12/Box - Sold As 1 Box - High quality. - Value priced bulk quantities. - Manufactured for professional and industrial applications. - Secure seal corrosion resistance. - Date coded.

Most promising application fields of linear drives for industrial applications:

•machine tools: machining center, skimming, grinding, milling, cutting, blanking and high speed machines.

•automation: handling systems, wafer handling, packing machines, pick-and-place

machines, packaging machines, automatic tester, printing technology

•general mechanical engineering: laser machining, bonder for semiconductor industry,

printed board machining, measurement machines, paper, plastic, wood, glass machining

Industrial Organization: Contemporary Theory and Empirical Applications

High speed applications

Industrial Applications of Batteries: From Cars to Aerospace and Energy Storage

In the magnet high-speed train Transrapid wheels and rail are replaced by a contact-less

working electromagnetic float and drive system. The floating system is based on attractive forces of the electromagnet in the vehicle and on the ferro-magnetic reaction rails in the railway. Bearing magnets pull the vehicle from below to the railway, guide magnets keep it on its way. An electronic control system makes sure, that the vehicle always floats in the same distance to the railway. Transrapid motor is a long-stator linear motor. Stators with moving field windings are installed on both sides along the railway. Supplied three-phase current generates an electromagnetic moving field within windings. The bearing magnets, and so also the vehicle are pulled by this field. Long-stator linear motor is divided into several sections. The section, in which the vehicle is located, is switched on. Sections, that make high demands on thrust, motor power is increased as necessary. Drive integrated in the railway and cancelling of mechanical components make magnet high-speed vehicles technical easier and safer. Transrapid consists of two light weight constructed elements. Capacity of the vehicles can be adjusted to certain requirements. Operating speed is between 300 and 500 km/h. A linear alternator supplies floating vehicle with required power. Advantages of magnet highspeed train are effective in all speed areas. After driving only 5 km Transrapid reaches a speed of 300 km/h in contrast to modern trains needing at least a distance of 30 km. Comfort is not interfered with jolts and vibrations. Since vehicle surrounds the railway Transrapid is absolutely safe from derailment. Magnet high-speed train makes less noise than conventional railway systems because there is no rolling noise. Also energy consumption is reduced

compared with modern trains. This high-speed system is tested in continues operation at a

testing plant in Emsland in Germany and some commercial routes in Germany are planned. A high-speed train route is currently under construction in Shanghai, China, further projects areeither in progress or under review.

Industrial application opportunities

Two different opportunities to implement linear drives are shown at the following pictures.

Duracell Products - Duracell - Procell Alkaline Battery, 9V, 12/Box - Sold As 1 Box - High quality. - Value priced bulk quantities. - Manufactured for professional and industrial applications. - Secure seal corrosion resistance. - Date coded.

Most promising application fields of linear drives for industrial applications:

•machine tools: machining center, skimming, grinding, milling, cutting, blanking and high speed machines.

•automation: handling systems, wafer handling, packing machines, pick-and-place

machines, packaging machines, automatic tester, printing technology

•general mechanical engineering: laser machining, bonder for semiconductor industry,

printed board machining, measurement machines, paper, plastic, wood, glass machining

Industrial Organization: Contemporary Theory and Empirical Applications

High speed applications

Industrial Applications of Batteries: From Cars to Aerospace and Energy Storage

In the magnet high-speed train Transrapid wheels and rail are replaced by a contact-less

working electromagnetic float and drive system. The floating system is based on attractive forces of the electromagnet in the vehicle and on the ferro-magnetic reaction rails in the railway. Bearing magnets pull the vehicle from below to the railway, guide magnets keep it on its way. An electronic control system makes sure, that the vehicle always floats in the same distance to the railway. Transrapid motor is a long-stator linear motor. Stators with moving field windings are installed on both sides along the railway. Supplied three-phase current generates an electromagnetic moving field within windings. The bearing magnets, and so also the vehicle are pulled by this field. Long-stator linear motor is divided into several sections. The section, in which the vehicle is located, is switched on. Sections, that make high demands on thrust, motor power is increased as necessary. Drive integrated in the railway and cancelling of mechanical components make magnet high-speed vehicles technical easier and safer. Transrapid consists of two light weight constructed elements. Capacity of the vehicles can be adjusted to certain requirements. Operating speed is between 300 and 500 km/h. A linear alternator supplies floating vehicle with required power. Advantages of magnet highspeed train are effective in all speed areas. After driving only 5 km Transrapid reaches a speed of 300 km/h in contrast to modern trains needing at least a distance of 30 km. Comfort is not interfered with jolts and vibrations. Since vehicle surrounds the railway Transrapid is absolutely safe from derailment. Magnet high-speed train makes less noise than conventional railway systems because there is no rolling noise. Also energy consumption is reduced

compared with modern trains. This high-speed system is tested in continues operation at a

testing plant in Emsland in Germany and some commercial routes in Germany are planned. A high-speed train route is currently under construction in Shanghai, China, further projects areeither in progress or under review.

Subscribe to:

Comments (Atom)

Labels

PROJECTS

8086 PIN CONFIGURATION

80X86 PROCESSORS

TRANSDUCERS

8086 – ARCHITECTURE

Hall-Effect Transducers

INTEL 8085

OPTICAL MATERIALS

BIPOLAR TRANSISTORS

INTEL 8255

Optoelectronic Devices

Thermistors

thevenin's theorem

MAXIMUM MODE CONFIGURATION OF 8086 SYSTEM

ASSEMBLY LANGUAGE PROGRAMME OF 80X86 PROCESSORS

POWER PLANT ENGINEERING

PRIME MOVERS

8279 with 8085

MINIMUM MODE CONFIGURATION OF 8086 SYSTEM

MISCELLANEOUS DEVICES

MODERN ENGINEERING MATERIALS

8085 Processor- Q and A-1

BASIC CONCEPTS OF FLUID MECHANICS

OSCILLATORS

8085 Processor- Q and A-2

Features of 8086

PUMPS AND TURBINES

8031/8051 MICROCONTROLLER

Chemfet Transducers

DIODES

FIRST LAW OF THERMODYNAMICS

METHOD OF STATEMENTS

8279 with 8086

HIGH VOLTAGE ENGINEERING

OVERVOLATGES AND INSULATION COORDINATION

Thermocouples

8251A to 8086

ARCHITECTURE OF 8031/8051

Angle-Beam Transducers

DATA TRANSFER INSTRUCTIONS IN 8051/8031

INSTRUCTION SET FOR 8051/8031

INTEL 8279

KEYBOARD AND DISPLAY INTERFACES USING 8279

LOGICAL INSTRUCTIONS FOR 8051/8031

Photonic Transducers

TECHNOLOGICAL TIPS

THREE POINT STARTER

8257 with 8085

ARITHMETIC INSTRUCTIONS IN 8051/8031

LIGHTNING PHENOMENA

Photoelectric Detectors

Physical Strain Gage Transducers

8259 PROCESSOR

APPLICATIONS OF HALL EFFECT

BRANCHING INSTRUCTIONS FOR 8051/8031

CPU OF 8031/8051

Capacitive Transducers

DECODER

Electromagnetic Transducer

Hall voltage

INTEL 8051 MICROCONTROLLER

INTEL 8251A

Insulation Resistance Test

PINS AND SIGNALS OF 8031/8051

Physical Transducers

Resistive Transducer

STARTERS

Thermocouple Vacuum Gages

USART-INTEL 8251A

APPLICATIONs OF 8085 MICROPROCESSOR

CAPACITANCE

Data Transfer Instructions In 8086 Processors

EARTH FAULT RELAY

ELECTRIC MOTORS

ELECTRICAL AND ELECTRONIC INSTRUMENTS

ELECTRICAL BREAKDOWN IN GASES

FIELD EFFECT TRANSISTOR (FET)

INTEL 8257

IONIZATION AND DECAY PROCESSES

Inductive Transducers

Microprocessor and Microcontroller

OVER CURRENT RELAY

OVER CURRENT RELAY TESTING METHODS

PhotoConductive Detectors

PhotoVoltaic Detectors

Registers Of 8051/8031 Microcontroller

Testing Methods

ADC INTERFACE

AMPLIFIERS

APPLICATIONS OF 8259

EARTH ELECTRODE RESISTANCE MEASUREMENT TESTING METHODS

EARTH FAULT RELAY TESTING METHODS

Electricity

Ferrodynamic Wattmeter

Fiber-Optic Transducers

IC TESTER

IC TESTER part-2

INTERRUPTS

Intravascular imaging transducer

LIGHTNING ARRESTERS

MEASUREMENT SYSTEM

Mechanical imaging transducers

Mesh Current-2

Millman's Theorem

NEGATIVE FEEDBACK

Norton's

Polarity Test

Potentiometric transducers

Ratio Test

SERIAL DATA COMMUNICATION

SFR OF 8051/8031

SOLIDS AND LIQUIDS

Speed Control System 8085

Stepper Motor Control System

Winding Resistance Test

20 MVA

6-digits

6-digits 7-segment LEDs

7-segment

A-to-D

A/D

ADC

ADVANTAGES OF CORONA

ALTERNATOR BY POTIER & ASA METHOD

ANALOG TO DIGITAL CONVERTER

AUXILIARY TRANSFORMER

AUXILIARY TRANSFORMER TESTING

AUXILIARY TRANSFORMER TESTING METHODS

Analog Devices

A–D

BERNOULLI’S PRINCIPLE

BUS BAR

BUS BAR TESTING

Basic measuring circuits

Bernoulli's Equation

Bit Manipulation Instruction

Buchholz relay test

CORONA POWER LOSS

CURRENT TRANSFORMER

CURRENT TRANSFORMER TESTING

Contact resistance test

Current to voltage converter

DAC INTERFACE

DESCRIBE MULTIPLY-EXCITED

Digital Storage Oscilloscope

Display Driver Circuit

E PROMER

ELPLUS NT-111

EPROM AND STATIC RAM

EXCITED MAGNETIC FIELD

Electrical Machines II- Exp NO.1

Energy Meters

FACTORS AFFECTING CORONA

FLIP FLOPS

Fluid Dynamics and Bernoulli's Equation

Fluorescence Chemical Transducers

Foil Strain Gages

HALL EFFECT

HIGH VOLTAGE ENGG

HV test

HYSTERESIS MOTOR

Hall co-efficient

Hall voltage and Hall Co-efficient

High Voltage Insulator Coating

Hot-wire anemometer

How to Read a Capacitor?

IC TESTER part-1

INSTRUMENT TRANSFORMERS

Importance of Hall Effect

Insulation resistance check

Insulator Coating

Knee point Test

LEDs

LEDs Display Driver

LEDs Display Driver Circuit

LM35

LOGIC CONTROLLER

LPT

LPT PORT

LPT PORT EXPANDER

LPT PORT

LPT PORT EXTENDER

Life Gone?

MAGNETIC FIELD

MAGNETIC FIELD SYSTEMS

METHOD OF STATEMENT FOR TRANSFORMER STABILITY TEST

METHODS OF REDUCING CORONA EFFECT

MULTIPLY-EXCITED

MULTIPLY-EXCITED MAGNETIC FIELD SYSTEMS

Mesh Current

Mesh Current-1

Moving Iron Instruments

Multiplexing

Network Theorems

Node Voltage Method

On-No Load And On Load Condition

PLC

PORT EXTENDER

POTIER & ASA METHOD

POWER TRANSFORMER

POWER TRANSFORMER TESTING

POWER TRANSFORMER TESTING METHODS

PROGRAMMABLE LOGIC

PROGRAMMABLE LOGIC CONTROLLER

Parallel Port EXPANDER

Paschen's law

Piezoelectric Wave-Propagation Transducers

Potential Transformer

RADIO INTERFERENCE

RECTIFIERS

REGULATION OF ALTERNATOR

REGULATION OF THREE PHASE ALTERNATOR

Read a Capacitor

SINGLY-EXCITED

SOLIDS AND LIQUIDS Classical gas laws

Secondary effects

Semiconductor strain gages

Speaker Driver

Strain Gages

Streamer theory

Superposition

Superposition theorem

Swinburne’s Test

TMOD

TRANSFORMER TESTING METHODS

Tape Recorder

Three-Phase Wattmeter

Transformer Tap Changer

Transformer Testing

Vector group test

Virus Activity

Voltage Insulator Coating

Voltage To Frequency Converter

Voltage to current converter

What is analog-to-digital conversion

Windows work for Nokia

capacitor labels

excitation current test

magnetic balance

voltage to frequency converter wiki electronic frequency converter testing voltage with a multimeter 50 hz voltages voltmeter